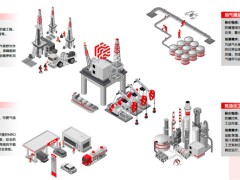

据安迅思新加坡3月10日消息,韩国炼油商双龙炼油公司(S-Oil)已开始在蔚山建设其原油制化学品项目,该项目预计将为韩国提供3万亿韩元(23亿美元)的附加值。

双龙炼油公司在一份声明中表示,该项目于3月9日举行了破土动工仪式,该项目名为沙欣(阿拉伯语为猎鹰),在建设高峰期间将创造17000个就业岗位,投产后将支持400多个就业岗位。

沙特阿美通过其子公司阿美海外公司拥有双龙炼油公司超过63%的股份。

该项目位于韩国蔚山市温山工业园区,计划于2026年竣工。

该项目将包括一个180万吨/年的混合进料裂解设施。

该项目还将包括年产88万吨线型低密度聚乙烯(LLDPE)装置以及年产44万吨高密度聚乙烯(HDPE)装置。

韩国双龙炼油公司表示:“沙欣项目将显著改善石化原料的稳定供应,并使蔚山的乙烯生产能力增加一倍以上。它还将通过管道向相邻的下游烯烃加工企业供应单体产品。”

双龙炼油公司表示,该生产基地还将有一个热原油制化学品(TC2C)设施,将原油直接转化为液化石油气(LPG)和石脑油等石化原料,裂解装置预计将回收废热用于炼油厂发电。

双龙炼油公司表示:“随着T2C2新技术的应用,原油和其他低价值重油将被升级为蒸汽裂解装置的原料,该技术将首次实现商业化。”

双龙炼油公司表示,一旦该项目完成,石化产品在公司总产量中的份额将从目前的12%增加一倍以上,达到25%。

包括2018年完成的一期项目,蔚山原油制化学品项目的总投资为14万亿美元,这是沙特阿美在韩国有史以来最大的投资。

庞晓华 摘译自 ICIS

原文如下:

S Korea’s S-Oil begins building $7bn crude-to-chemicals Shaheen project in Ulsan

South Korean refiner S-Oil has started building its crude-to-chemicals project in Ulsan which is expected to provide won (W) 3tr ($2.3bn) in added value to the northeast Asian economy.

A groundbreaking ceremony was conducted on 9 March for the project called Shaheen – Arabic word for falcon – which should generate up to 17,000 jobs during peak construction, and after start-up, should support more than 400 jobs, S-Oil said in a statement.

The company is over 63%-owned by Saudi Aramco through its subsidiary Aramco Overseas Co.

The project located at the onsan Industrial Complex of Ulsan City is slated to be completed in 2026.

It will include a 1.8m tonne/year mixed-feed cracking facility.

The project will further include a 880,000 tonne/year linear low density polyethylene (LLDPE) unit; and a 440,000 tonne/year high density polyethylene (HDPE) plant.

“Shaheen will significantly improve the stable supply of petrochemical feedstock and more than double ethylene production capacity in Ulsan. It will also supply monomer products through a pipeline to adjacent downstream olefin-processing businesses,” S-Oil said.

The site will also have a thermal crude-to-chemical (TC2C) facility which will convert crude directly into petrochemical feedstocks such as liquefied petroleum gas (LPG) and naphtha, and the cracker is expected to recycle waste heat for power generation in the refinery, the company said.

“With the deployment of this new [T2C2] technology, which is being commercialized for the first time, crude and other low value heavy oils will be upgraded into steam cracker feedstocks,” S-Oil said.

once the project is completed, petrochemical production will more than double its share to S-Oil’s total output to 25% from 12% currently, it said.

Including the first phase of the project completed in 2018, the total investment in Ulsan’s crude-to-chemical projects is W14tr – the largest ever for Saudi Aramco in South Korea.

免责声明:本网转载自其它媒体的文章及图片,目的在于弘扬石化精神,传递更多石化信息,宣传国家石化产业政策,展示国家石化产业形象,参与国际石化产业舆论竞争,提高国际石化产业话语权,并不代表本网赞同其观点和对其真实性负责,在此我们谨向原作者和原媒体致以崇高敬意。如果您认为本站文章及图片侵犯了您的版权,请与我们联系,我们将第一时间删除。