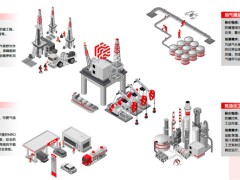

据烃加工新闻3月24日消息称,该3D工业试验展示了从工业活动中捕获二氧化碳的创新流程,目前正在安赛乐米塔尔敦克尔克工厂进行。在欧盟“地平线2020研究和创新计划”的支持下,该项目旨在验证可复制的碳捕获技术解决方案。该由道达尔能源、ArcelorMittal、Axens和IFP Energies Nouvelles (IFPEN)等财团推动的3D项目,是向脱碳行业迈出的重要一步,这些行业排放的二氧化碳很高,如炼钢。

碳捕获研究人员面临的挑战是,如何提高碳捕获过程的竞争力,降低能源消耗。这个工业试验应该可以验证DMXTM碳捕集工艺在过去十年中在IFPEN实验室中开发的性能。

该项目于 2019 年 5 月启动,并在 Axens 的监督下于 2020 年开始建造演示器。2021 年 12 月,试验的主要模块,包括一个 22米高的塔,在安赛乐米塔尔位于敦刻尔克的工厂交付和组装。建造试验装置并将其与工厂连接的阶段现已完成,该装置已准备好启动。

这次演示计划持续12-18个月,是该技术全面部署之前的最后阶段。

碳捕集设施将处理炼钢气体:它将通过将二氧化碳从其他气体中分离出来以证明碳捕集过程的有效性。在演示阶段,它每小时将捕获0.5吨二氧化碳,即超过4000吨/年。

朱佳妮 摘译自 烃加工新闻

原文如下:

TotalEnergies launches carbon capture pilot project in Dunkirk

The 3D industrial pilot to demonstrate an innovative process for capturing CO2 from industrial activities is now running at ArcelorMittal’s Dunkirk site. With support from the EU’s Horizon 2020 Research and Innovation programme, the project aims to validate replicable technical solutions for carbon capture. The 3D project, driven by a consortium including TotalEnergies, ArcelorMittal, Axens and IFP Energies Nouvelles (IFPEN), is a major step towards decarbonising industries that are highly emissive of CO2, such as steelmaking.

The challenge for carbon capture researchers is making the processes more competitive and less energy intensive. This industrial pilot should allow the performance of the DMXTM carbon capture process developed in IFPEN’s labs over the last ten years to be verified.

The project was launched in May 2019, and the building of the demonstrator began in 2020 under Axens’ supervision. In December 2021, the pilot’s main modules, including a 22 m tower, were delivered and assembled at ArcelorMittal’s site in Dunkirk. The phases of building the pilot and connecting it to the plant have now been completed, and the unit is ready for start-up.

This demonstration, which is scheduled to last for 12 – 18 months, is the final stage before the technology’s full-scale deployment.

The carbon capture facility will process steelmaking gases: it will demonstrate the effectiveness of the carbon capture process by separating the CO2 from other gases. During the demonstration stage, it will capture 0.5 t of CO2 an hour, i.e. more than 4000 tpy.

免责声明:本网转载自其它媒体的文章及图片,目的在于弘扬石化精神,传递更多石化信息,宣传国家石化产业政策,展示国家石化产业形象,参与国际石化产业舆论竞争,提高国际石化产业话语权,并不代表本网赞同其观点和对其真实性负责,在此我们谨向原作者和原媒体致以崇高敬意。如果您认为本站文章及图片侵犯了您的版权,请与我们联系,我们将第一时间删除。